Hi, just trying to get some advise on how to start creating an inventory managements base on airtable. We provide kits with have their own unique indentfying number - and each kit contains devices which we record the serial numbers of - they belong to each individual kit.

Is there a way to build this out so that the Kit ID "contains" the unique devices? But still make them moveable and flexible ?

We also will need to track stock that has not yet been built into a kit - but all with have unique serial numbers.

Many thanks for any insights!

Solved

Kit Inventory Management with parent and child components

+4

+4Best answer by TheTimeSavingCo

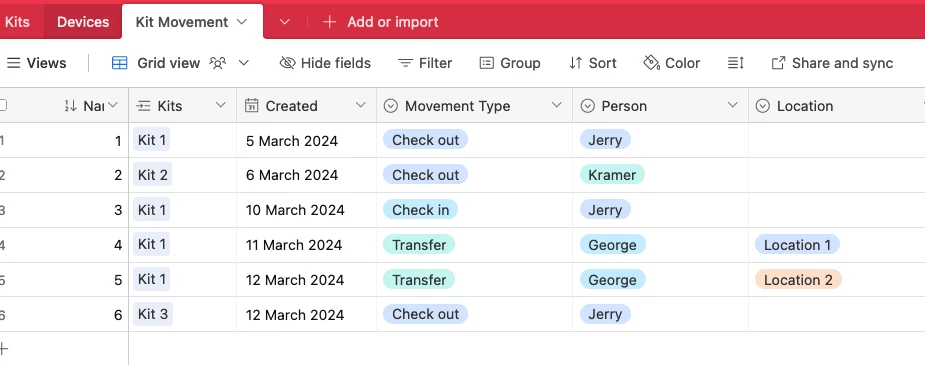

I think we would need to track historical data actually T_T

Here

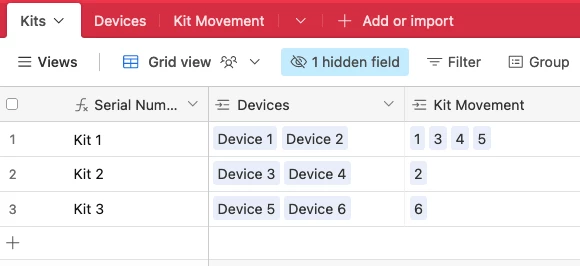

So you'll have Kits:

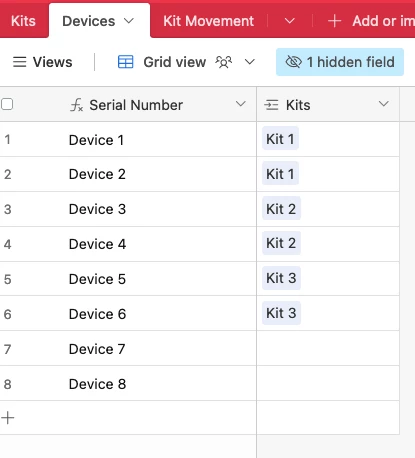

Devices:

And movement:

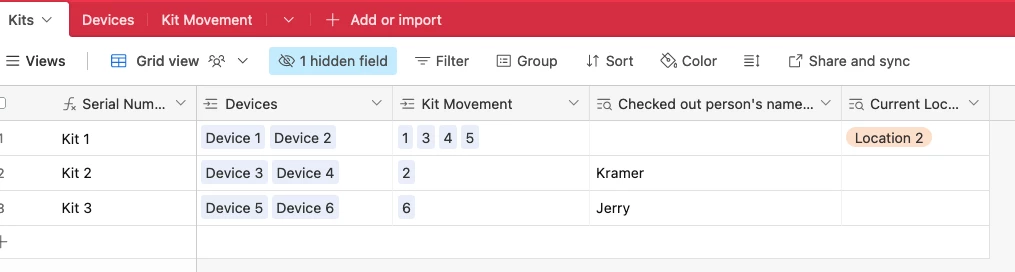

And for display purposes you could use formula / rollup / lookup fields to see who currently has the kit or where it's currently located:

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.