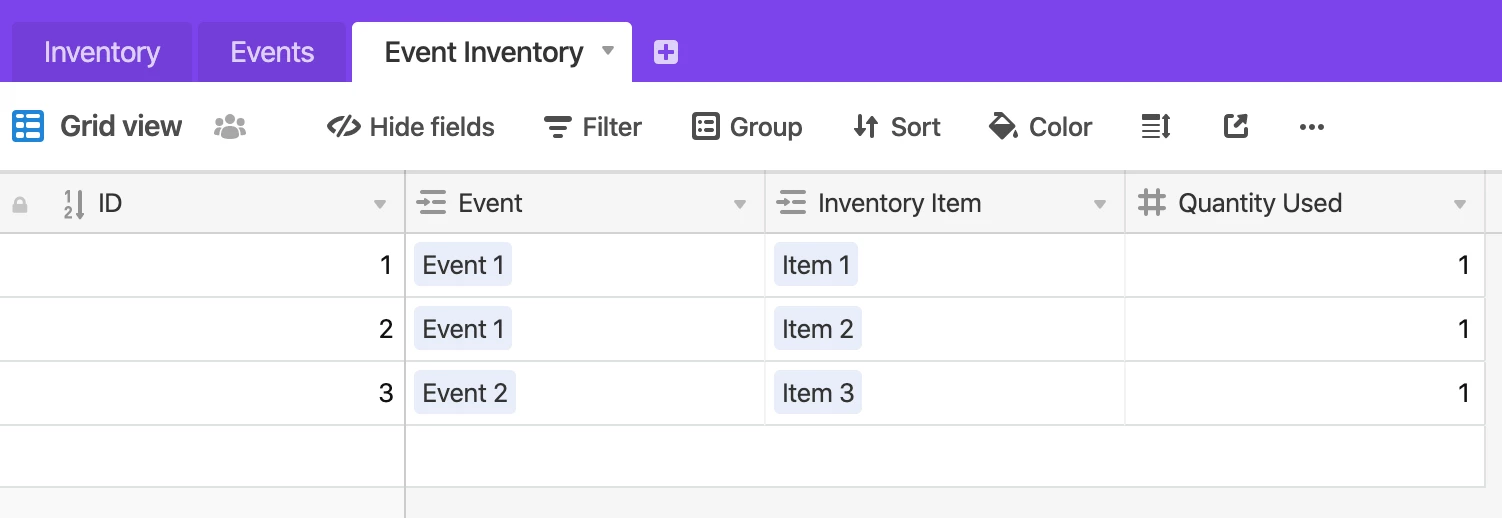

Hi folks! I have run into an issue that I can’t quite figure out. I have a base where I want to track inventory and profitability for our Event Decor company. The base has a table for Inventory items and a table for Events. On the inventory table I have a quantity field that is used to keep track of how many of a certain item we have in stock. In addition, this table tracks what events the items have been used for and also tracks the profitability of each inventory item.

The problem is when I have an inventory item with multiple quantities. I have no way to specify the quantity used for their event in the events table because every inventory item is displayed in 1 cell. This means that if we have two items in stock but the event only uses 1, I have no way to input that and then perform calculations on that.