Hi folks,

This is my first post on the forum as I'm just getting started with AirTable.

I've set up a sample AirTable project to explain what I'm looking to https://airtable.com/appEMeJBL3Crynbxm/shrghnubXMunVieh1

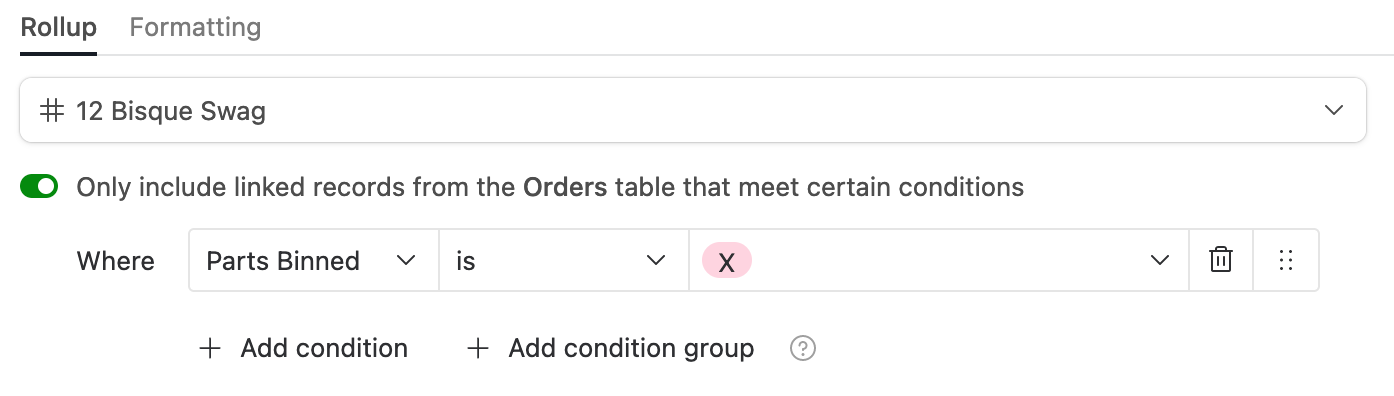

- There's an "Orders" table with all of the orders we receive from customers, and the parts that we need to fulfill those orders.

- There's an "Inventory" table with those exact same parts listed as records/rows rather than fields/columns. I want to sum all the parts required for open orders and display them in the Inventory Table "Required For Orders" field. Then it's just a simple calculation to get a read out on whether or not I have enough parts in inventory to fulfill the order.

My actual process has about 60 parts and hundreds of orders, but if I can figure out how to do the above it should be the same to set it up.

Thanks,

Ted