Hello!

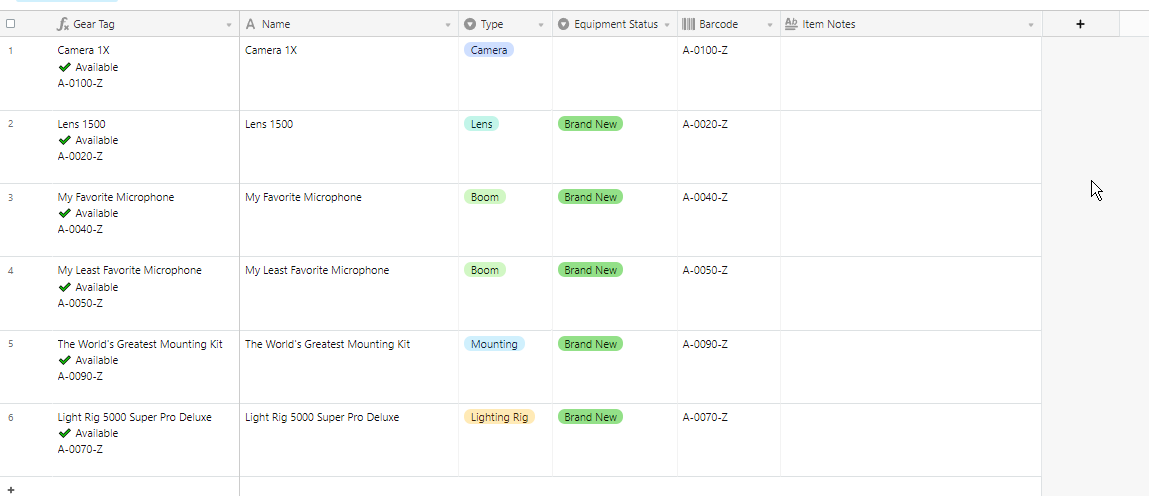

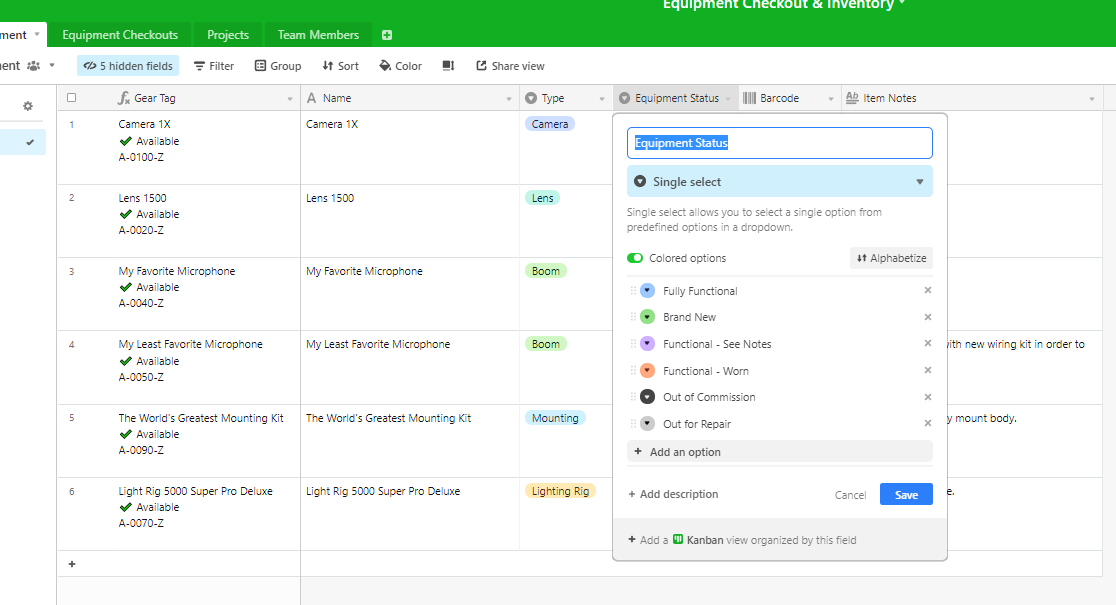

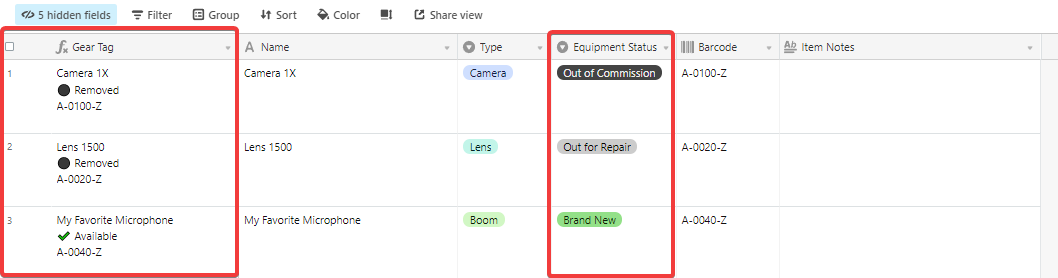

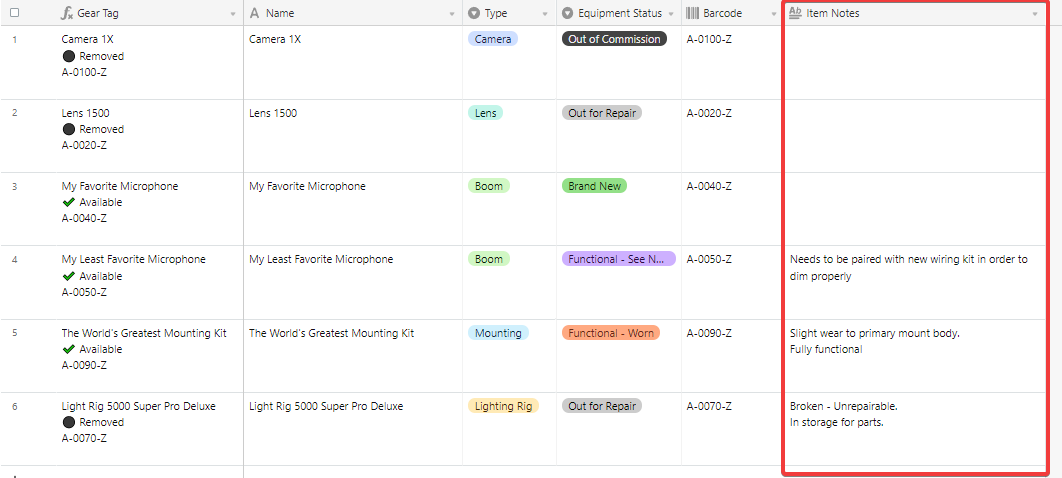

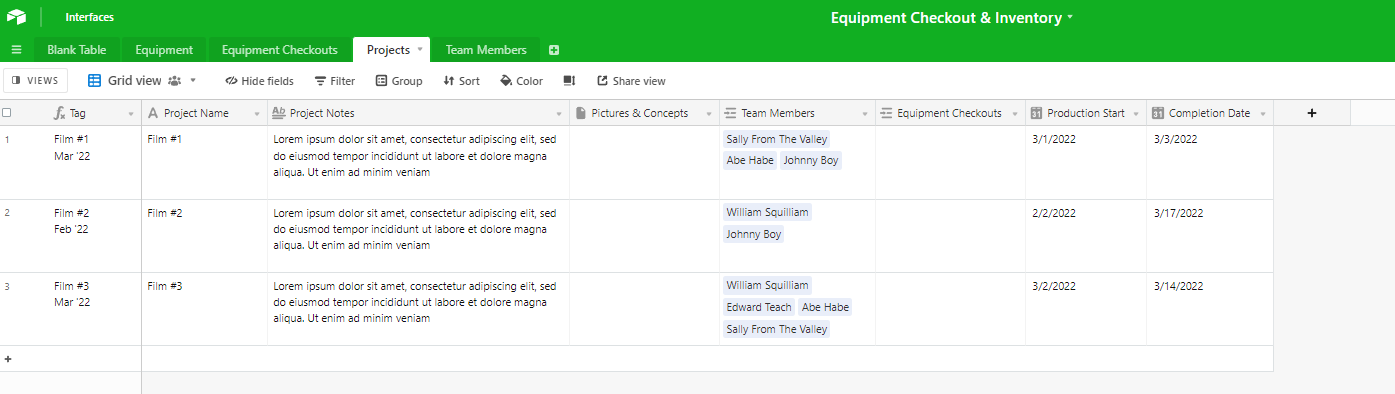

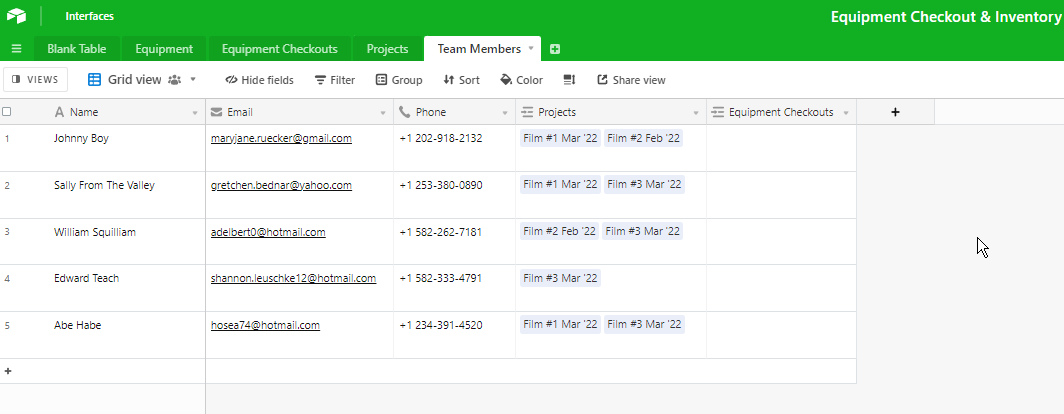

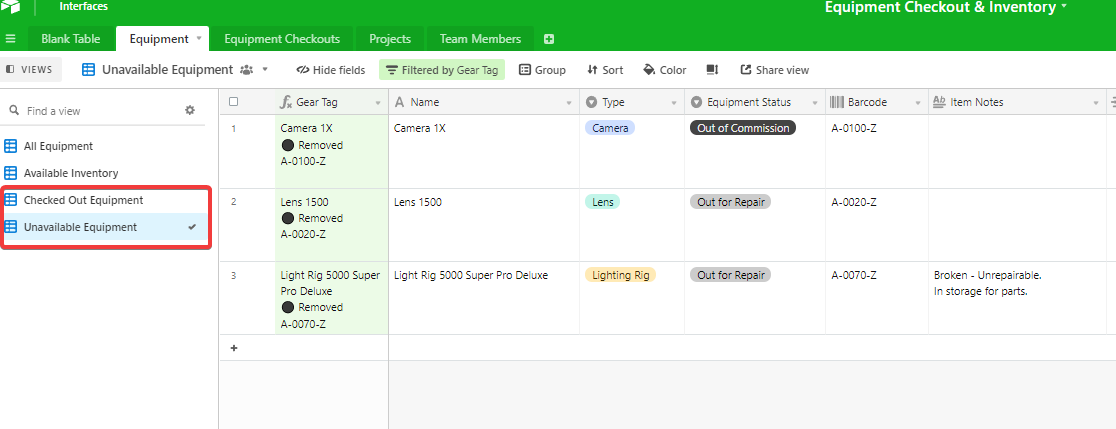

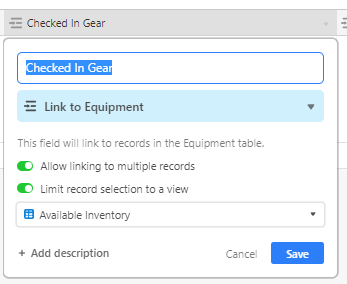

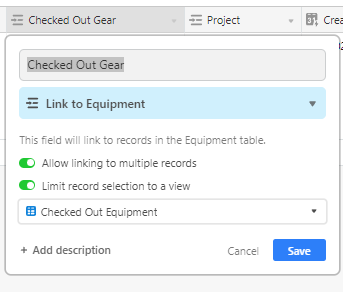

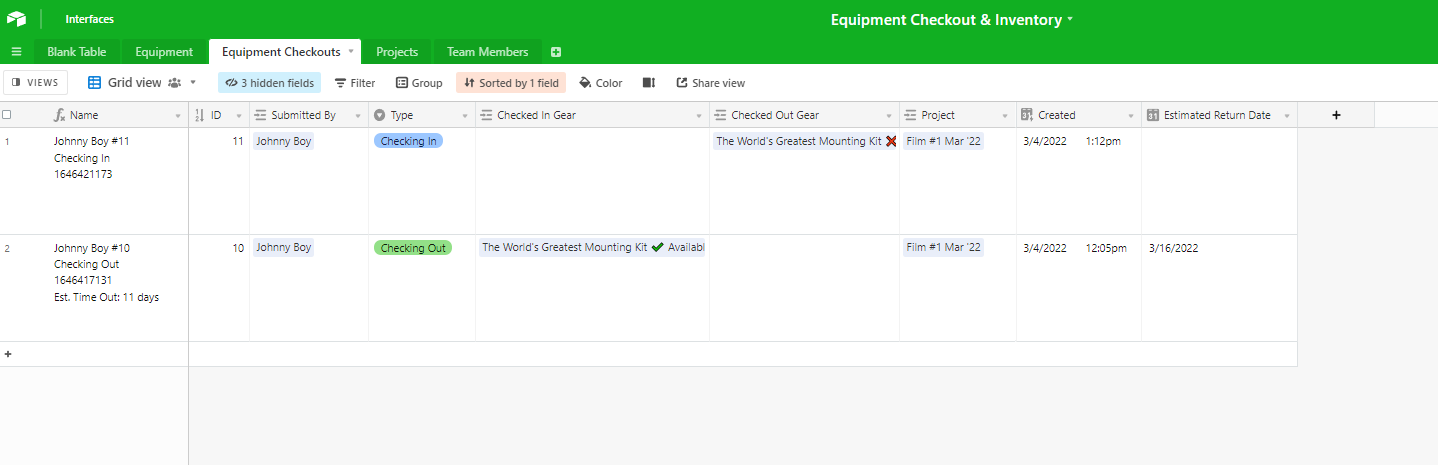

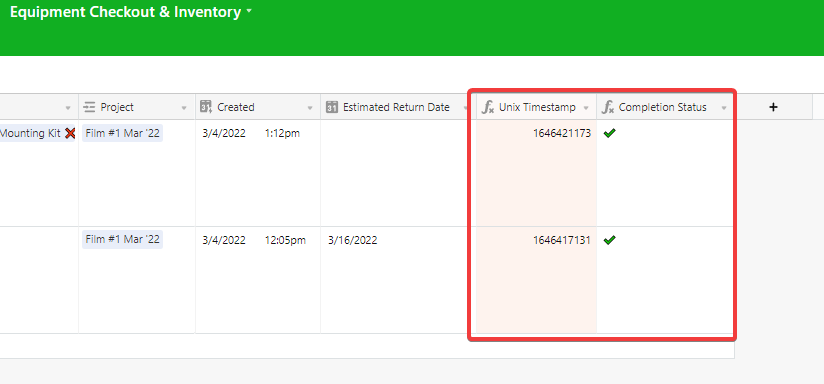

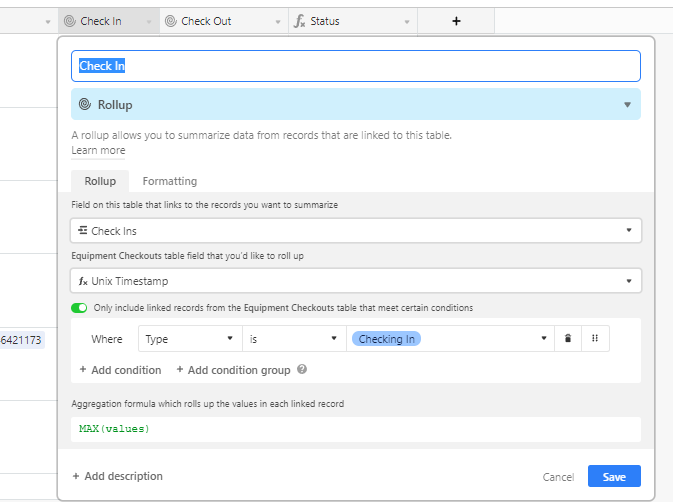

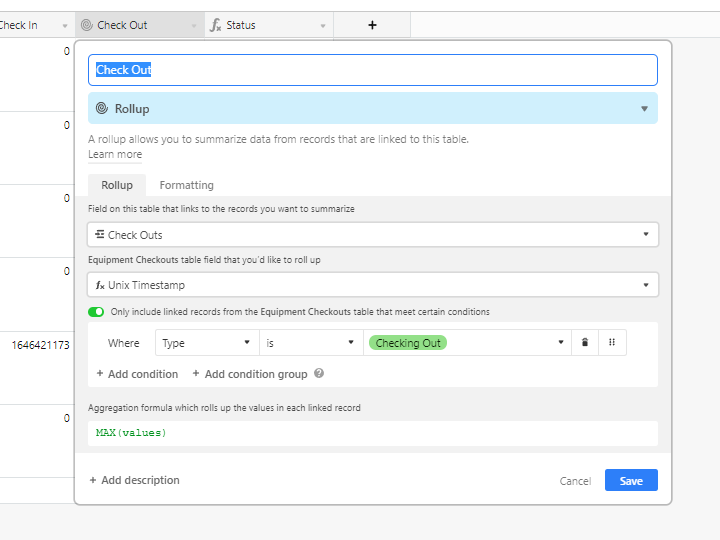

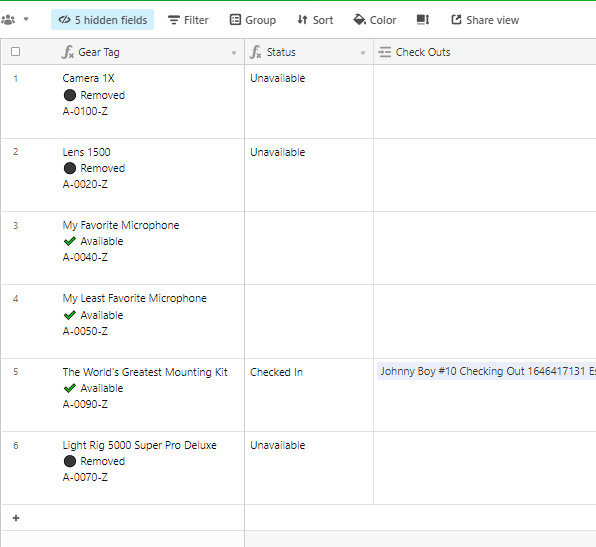

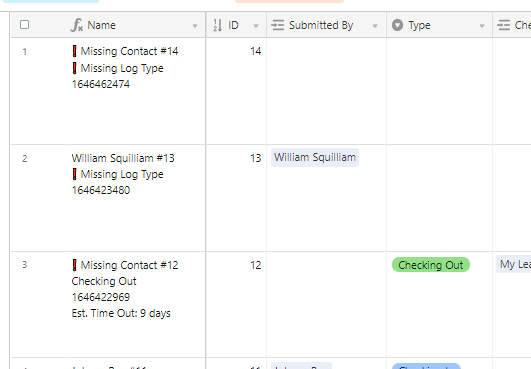

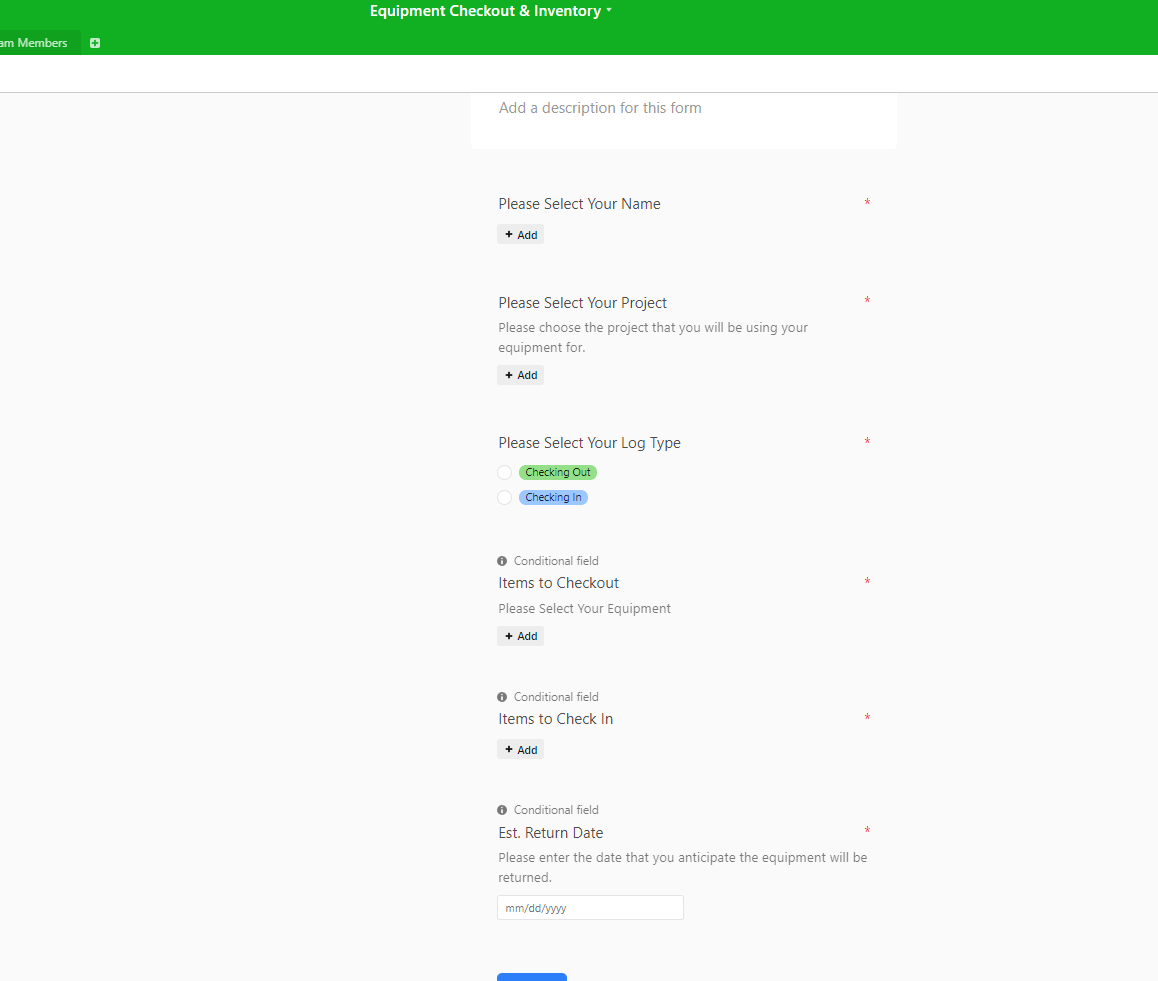

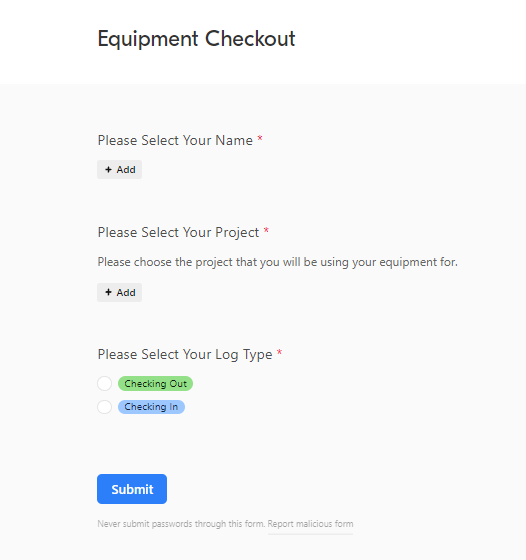

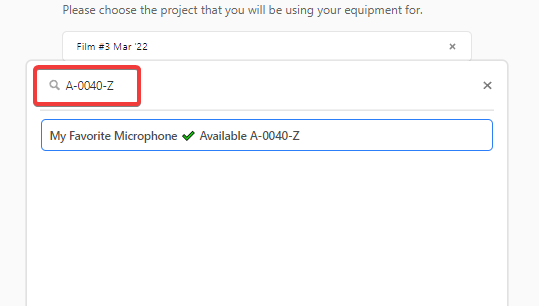

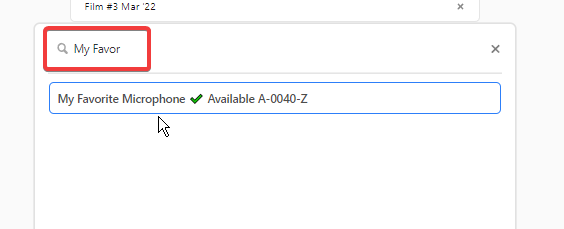

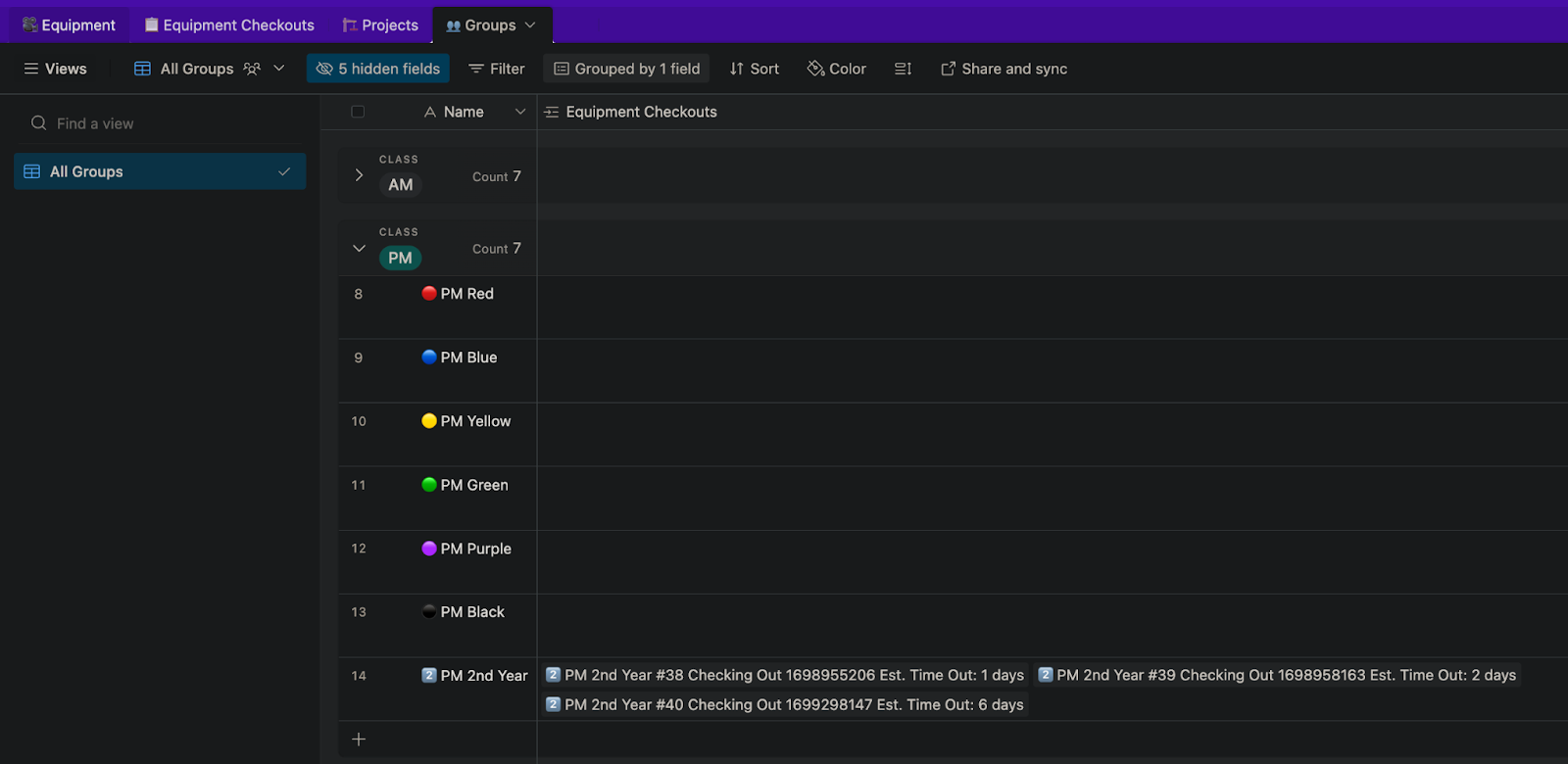

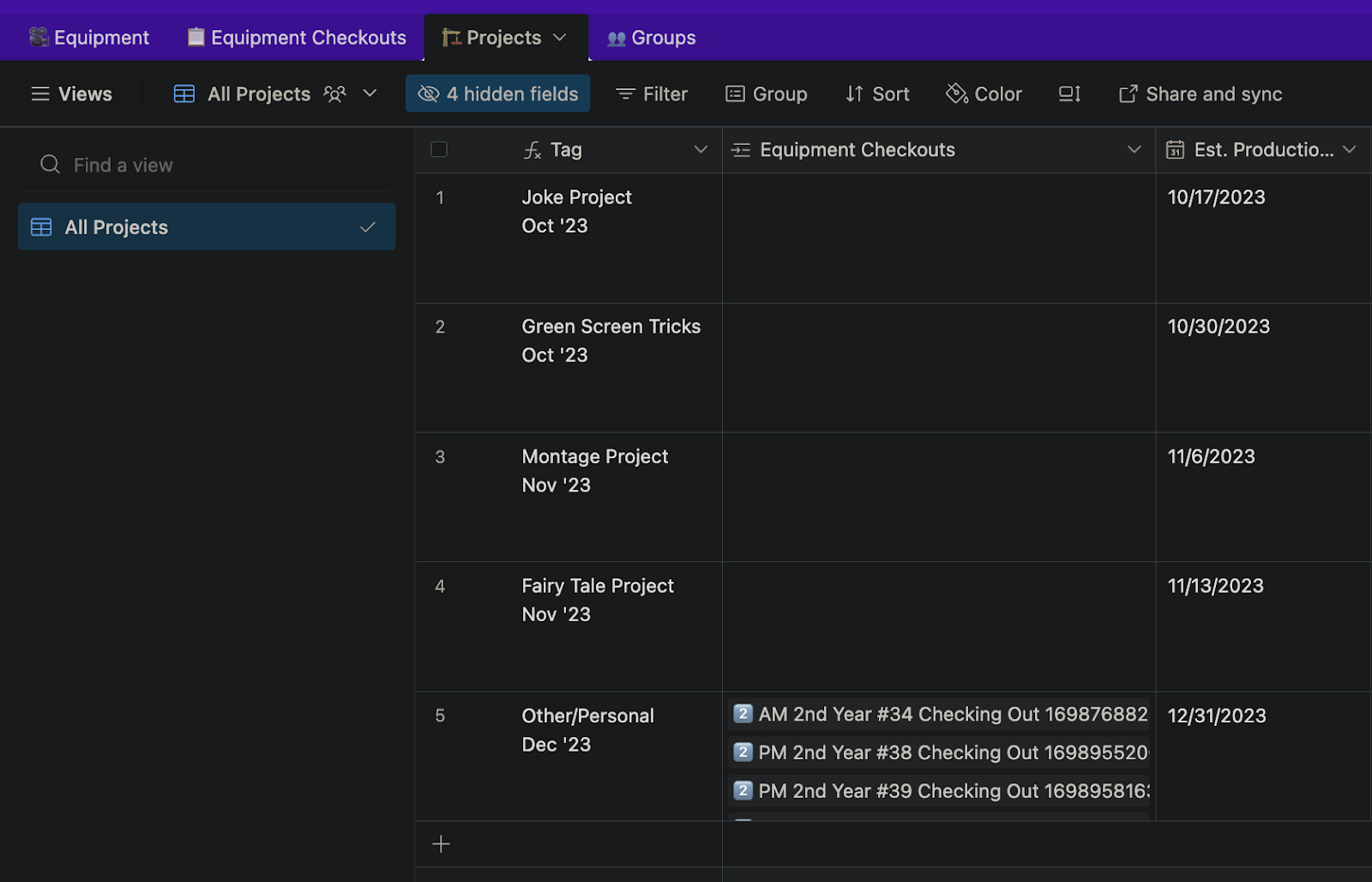

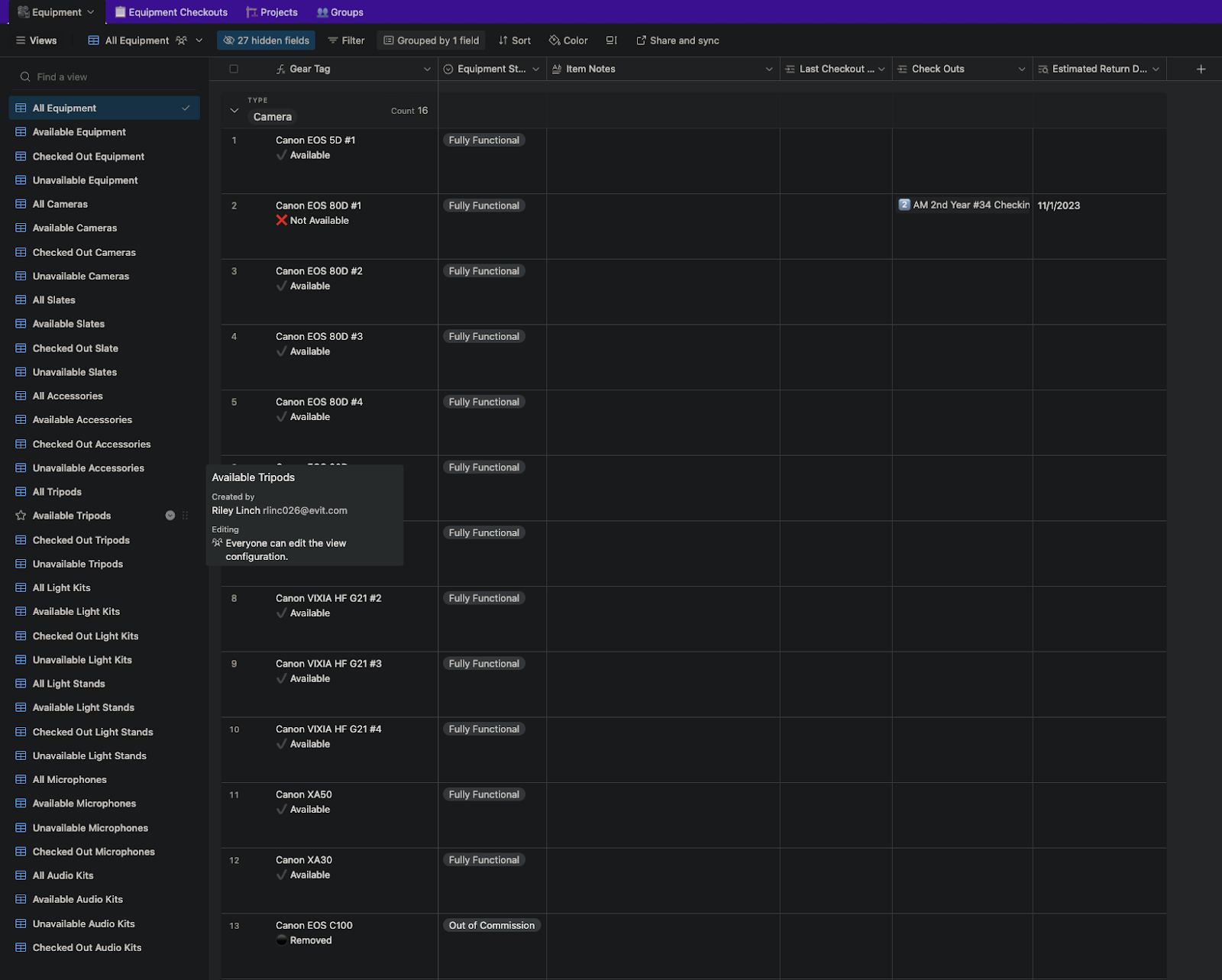

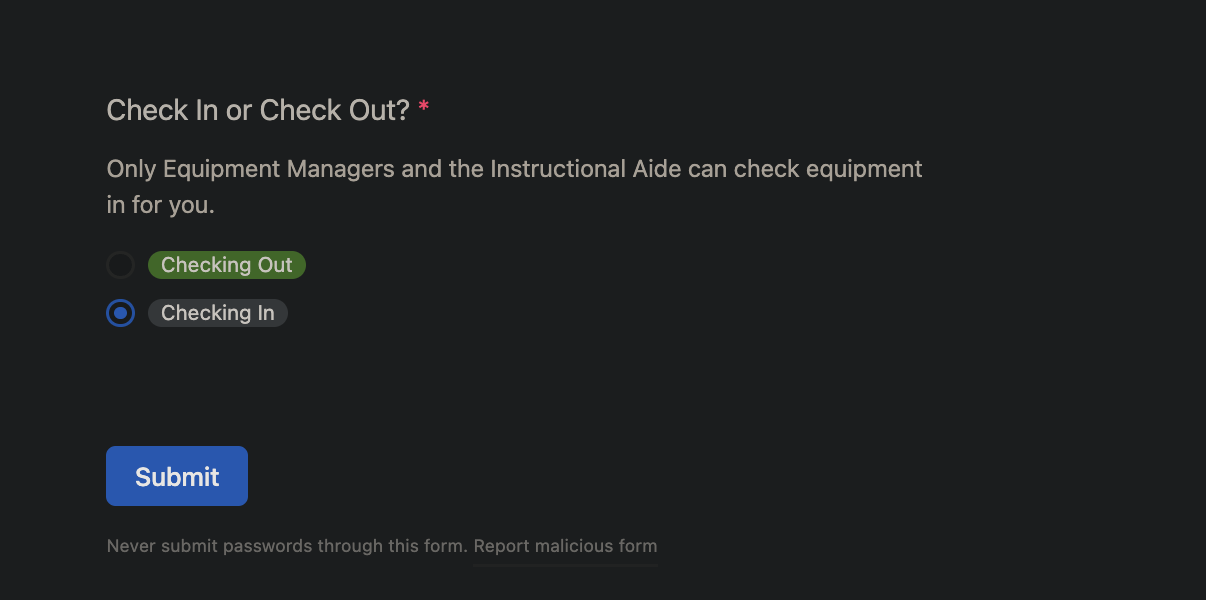

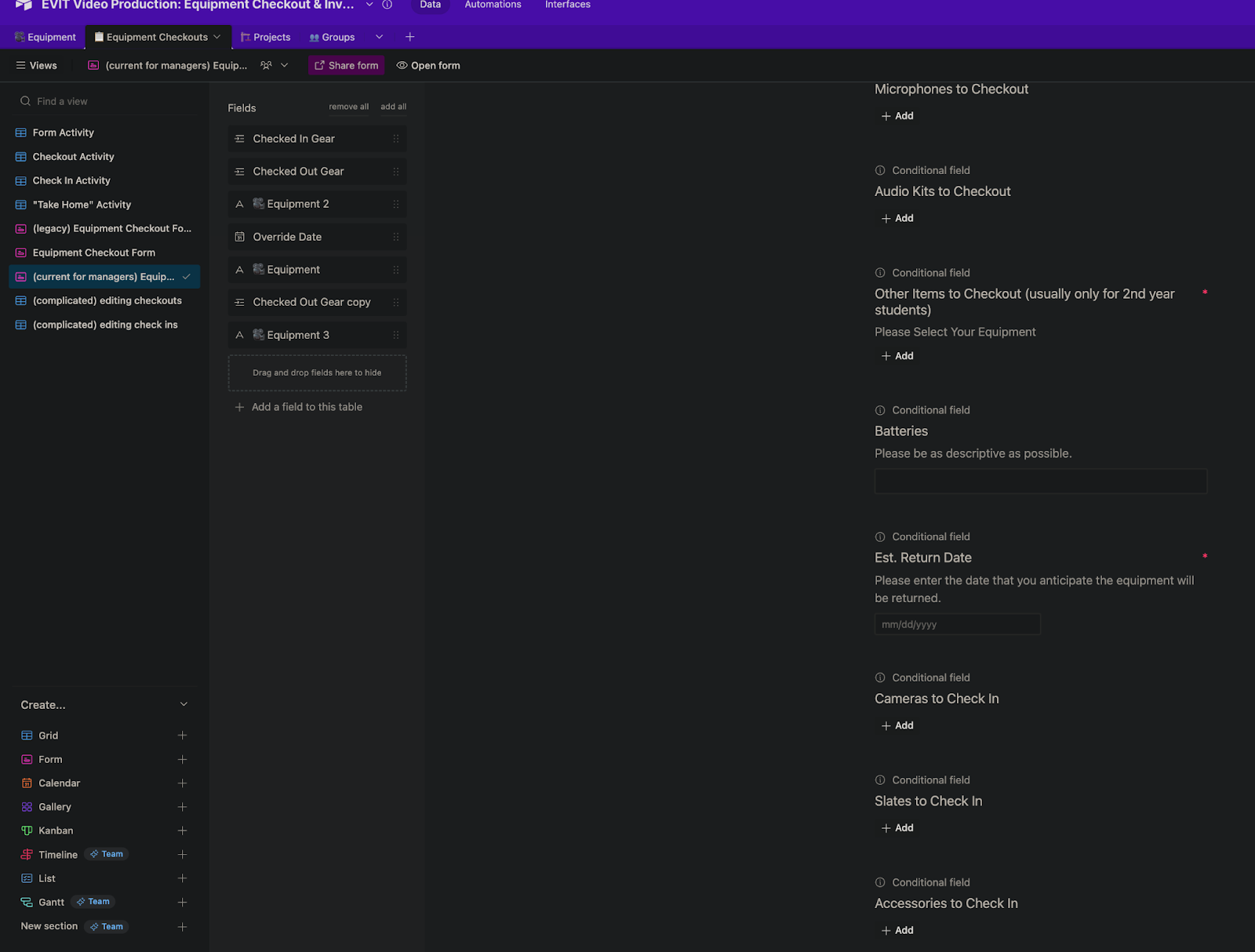

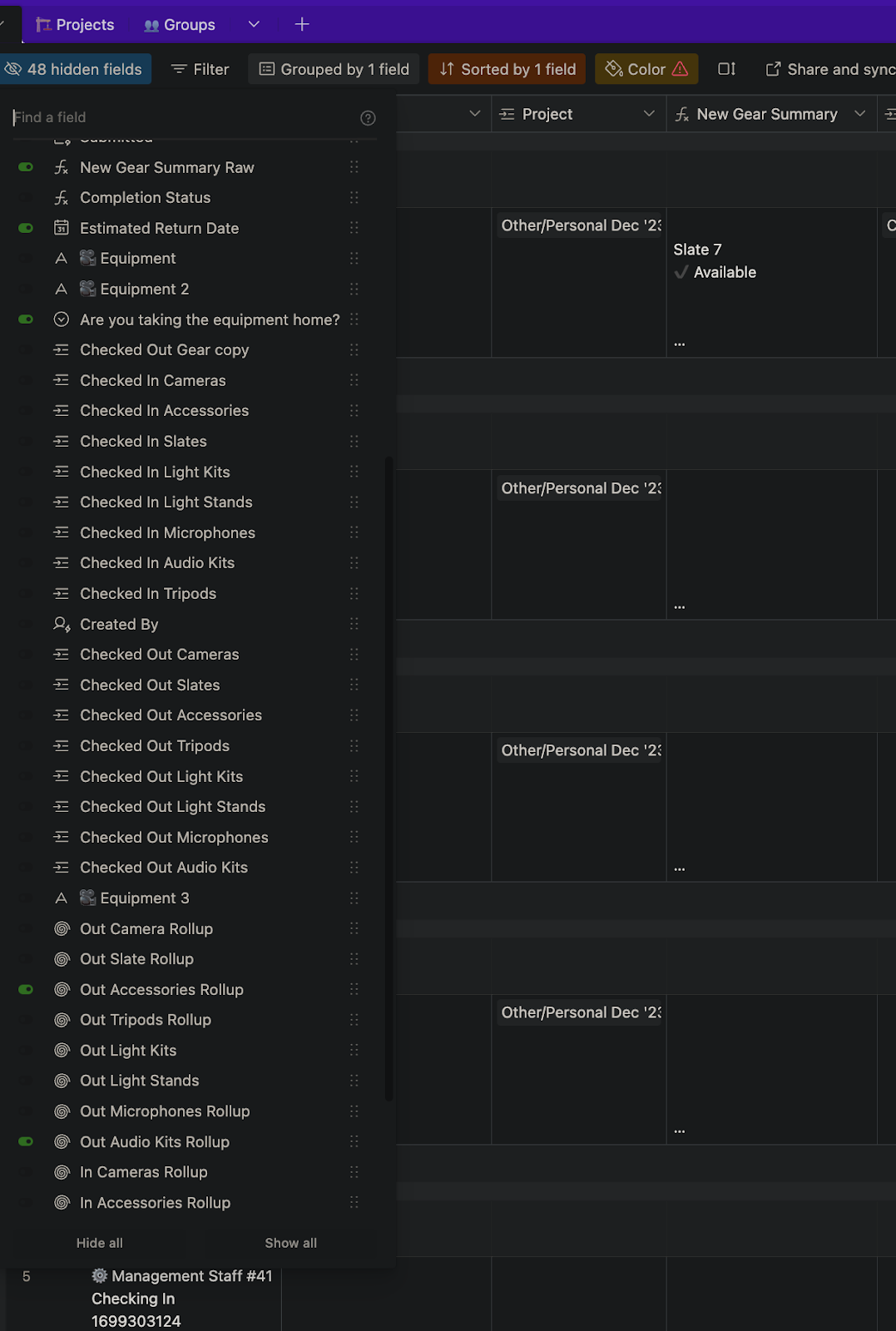

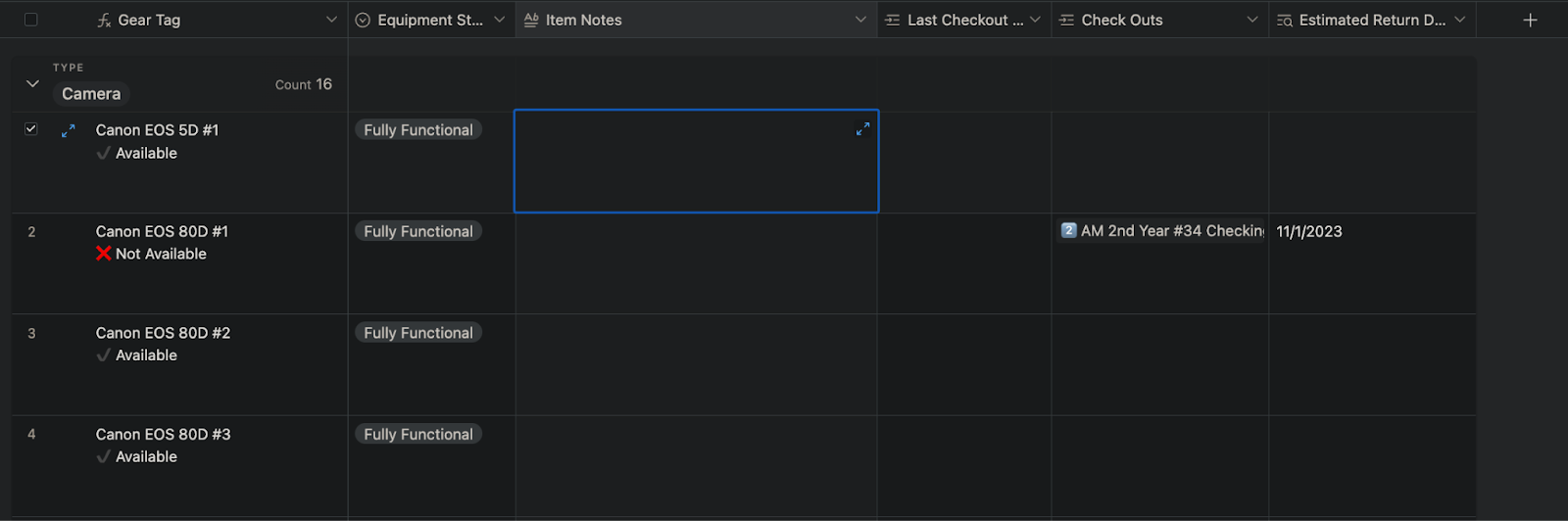

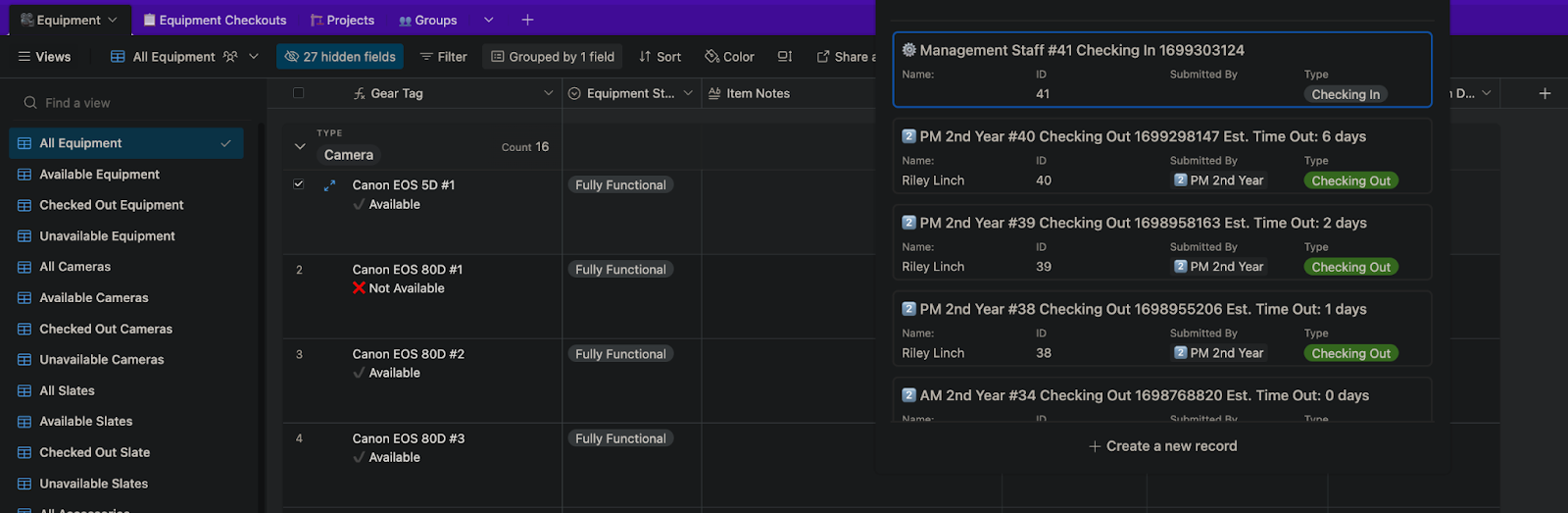

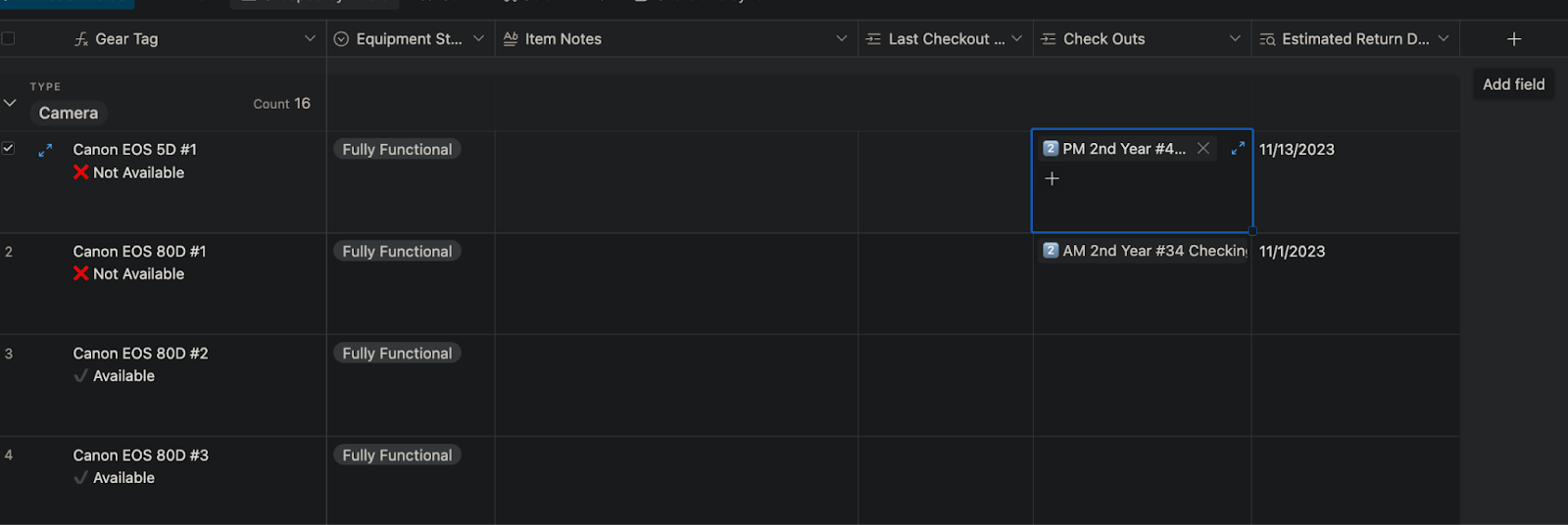

We have a small video production studio that has enough people to need a better solution to check out equipment. We set up a table with all of our inventory and a separate table that has all of our tasks. In the task table, we set up an equipment checkout form that allows has all the equipment categorized and available to check out. It’s the best solution that we have found so far but I feel like there has to be a better way. Currently, since the form is simply linking each item in the inventory table, they all show up as individual options, so we have to click the drop down box every, scroll, and select what we need instead every time we want to add an item in the same category. A checkbox-style set up like in a multiple select field would be the most ideal.

We have a label maker that can print out barcodes readable by airtable, so what if I can somehow set up a form/table/view that we can keep open in the equipment room and use a barcode scanner (we’re looking at the Tera Barcode Scanner at the moment) to scan multiple items at once, then input your name, the date you’ll need the equipment for, and have that information link back to the existing inventory and tasks tables.

Does that make sense? Is this doable? Is there another way that we can get around this?