Hello all,

I started a base and before I get too far I thought I might ask the community to help me start on the right track. I would like to track the fabrication of a lot of piping assemblies. Here is what I have in mind :

- One table for the list of pipe assemblies to track the drawing status (for comments, for construction)

- One table to track the fabrication status (drawing for construction received, in progress, completed, shipped to paint shop)

- For this step I would like to have an attachment for the invoice from the fab shop and the delivery bill from the fab shop to the paint shop

- One table to track the paint of each assemblies (received from fab shop, in progress, completed, shipped to work site)

- For this step I would like to have an attachment for the invoice from the paint shop and the delivery bill from the paint shop to the work site

- One table to track the receiving of each assembly to the work site (received from paint shop, installation in progress, completed, invoiced to client)

- For this step I would like to have an attachment for the material / installation bill and the invoice to the client

Am I on the right track? is it possible for the assembly number to be unique for the entire base?

Ultimately, before I create my invoice I would like to be able to combine all the attachment together in order to be able to invoice our client based on what was delivered to site. How could I do that?

Here is an example:

I have 50 drawings

10 of them have the “for construction” status and are sent to the fab shop in order to start the fabrication

Then, 5 of the assemblies are completed and are shipped to the paint shop

Then 4 of the completed assemblies are painted and we request to ship them to site to start the installation

4 assemblies are now on site and can now be invoiced

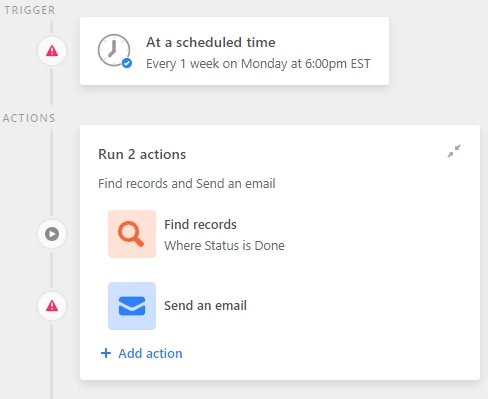

- Edit : I also would like to create an automation if an attachment is missing, send a reminder. For example if an assembly is shipped from the fab shop to the paint shop. I should have a delivery bill and I want to be reminded that the attachment is missing until I upload it to the table. (would it be possible to group all the missing document in one email? let say : assembly 1, 2 and 3 have been delivered but the delivery bill is missing)