The problem: Our manufacturer will ship the contents of a Purchase Order as they are made and ship the remaining products when completed. We have had several occurrences of not knowing what’s coming and what is left until it arrives and we open the box. (We have a middle man, there is no direct comms with the supplier).

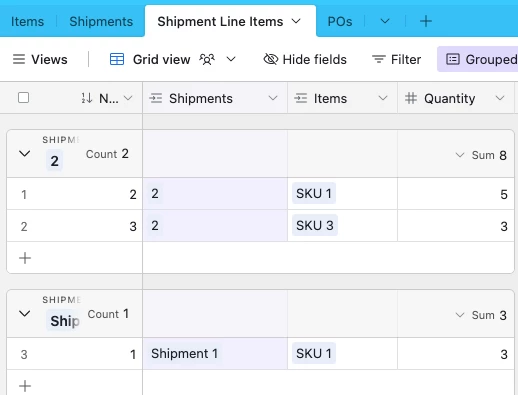

My goal: Build an interface that the manufacturer can open, select the PO number, and input how much of each SKU is in the upcoming shipment, and put in the tracking number.

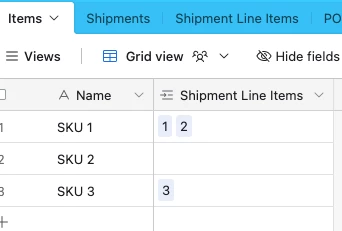

Where I’m at: I have a Master Products Base with all of my SKUs in one table, and purchase orders in another table. I can add my skus from the products table into each PO, but I can’t assign each sku an order qty within the PO record.

The other nuanced issue is that sometimes PO’s overlap and we will have the same SKUs on multiple POs. I want to be able to assign different order quantities to each SKU in a PO, and keep track of how many have been shipped from each PO.