You're going to need a junction table where each record represents a single item linked to a single kit, and contains the quantity of the item in that kit

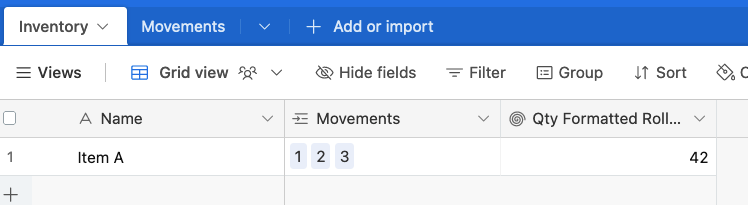

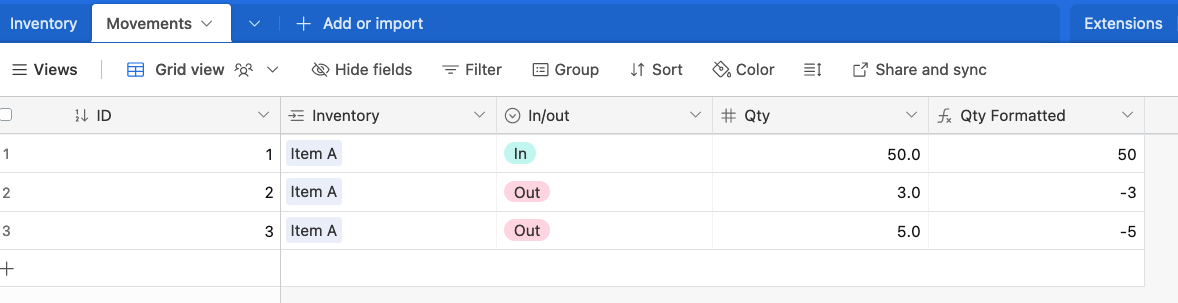

After that, it depends on how you're tracking your inventory, really. Personally I favour having a "Movements" table where each record represents a single item, the quantity moved, direction (in or out) and linked to the item's record in an "Inventory" table, and then I use rollups to sum up the quantity

With that method, I have an automation that'll look for all the records in the junction table that are linked to the kit and create one record for each of them to the "Movements" table, which updates my "Inventory" count appropriately

Thanks, still not clear on the "Movement" table though.

Thanks, still not clear on the "Movement" table though.

Here: