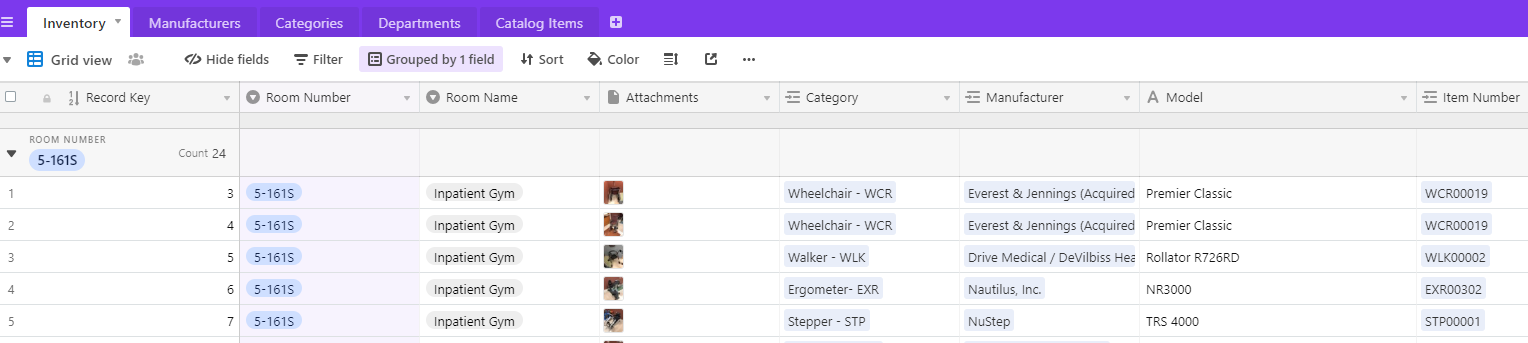

I’m new to Airtable and have been exploring it as a possible equipment inventory solution. I have a primary table called ‘Inventory’ within a base. Among the fields listed there are ‘Manufacturer’ and ‘Model,’ as well as ‘Item Number.’ ‘Item Number’ is a linked field, linking to a second table titled ‘Catalog Items’ which includes ‘Manufacturer’ and ‘Model’ fields and is based on an import from a separate database we use for planning.

I would ideally like users in the field to be able to enter ‘Manufacturer’ and ‘Model’ manually OR to be able to select an ‘Item Number’ and have that data populate from the ‘Catalog Items’ table to the ‘Manufacturer’ and ‘Model’ fields in the ‘Inventory’ table.

Much less importantly, if the field user populates the ‘Manufacturer’ and ‘Model’ fields in the ‘Inventory’ table and then decides to make a new ‘Item Number’ to add to that field, is there a way to have those fields populate back into the ‘Catalog Items’ table?

The goal is to not have folks in the field touch anything but the ‘Inventory’ table. I appreciate your help and hope that the question is not terribly redundant.