Hey guys,

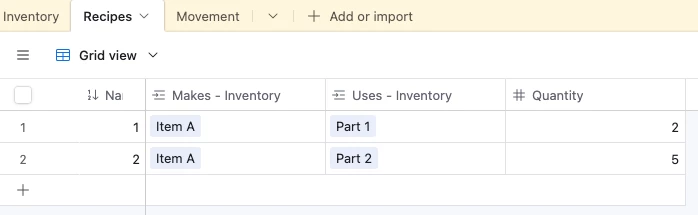

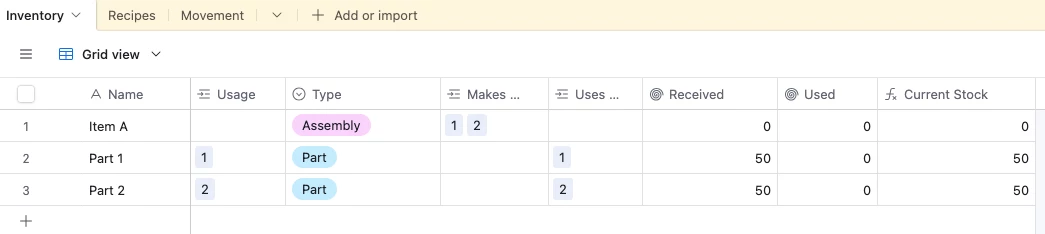

Anyone ever made a inventory management system that handled multi level assemblies? Looking to build something that will help me track assemblies with various quantities or parts inside them, various warehouse locations and hopefully also link back to zapier for integration with a website.

I would like to be using a full ERP system but they estimate months to have it implemented so looking for something in the mean time.

Database would only have around 70 finished parts made up from 200 or so parts total.

If anyone has a template would be amazing!

Thanks