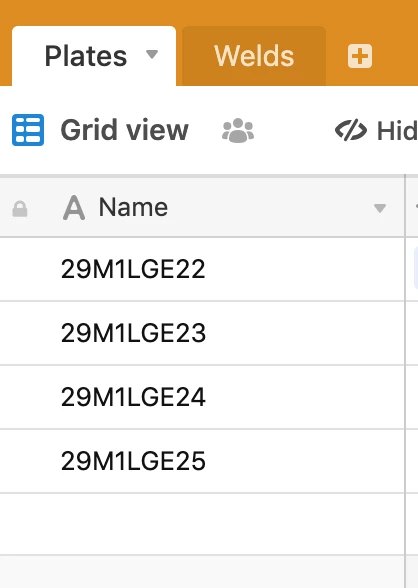

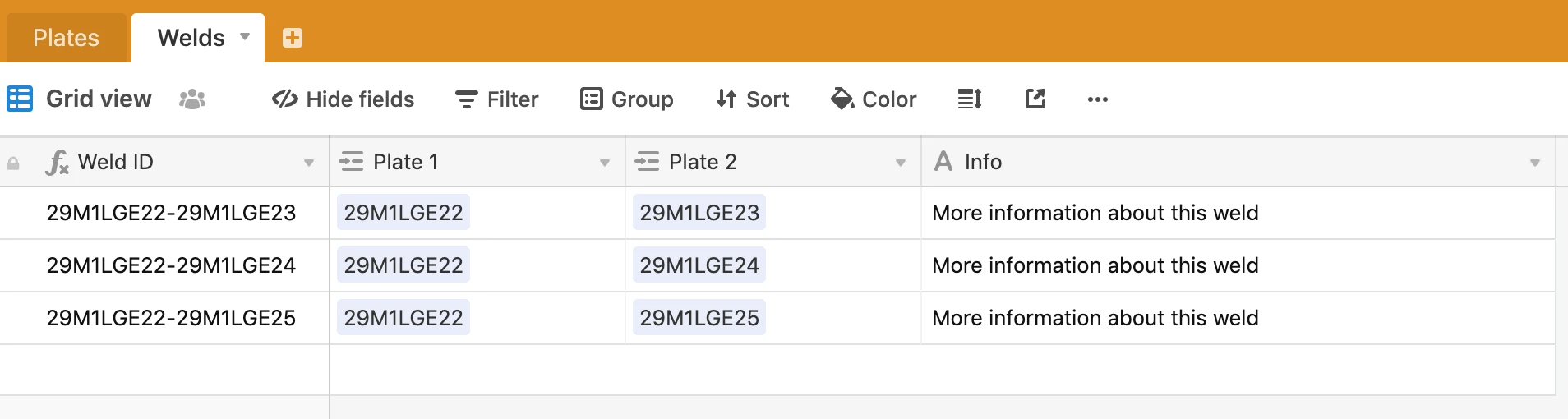

So possibly a unique case here that I haven’t seen anything on yet. Looking at using airtable for welding production tracking on a construction site. The work, in simple terms, is welding a bunch of steel plates together on a wall to make a continuous plate. If you can imagine a series of rectangles lined up on a wall, each seam between rectangles is a weld. We currently have a list of all individual plates on the job, and then have fairly complex ID #s (29M1LGE22 for example, each character defining a certain position).

The way you would identify what WELD you want to pull up would be to search two plates that are adjacent, and the weld ID would be the conjunction of those two plate IDs (is 29M1LGE22-29M1LGE23).

We will be doing many welds per day, so as you can imagine writing down or searching out every individual ID would be very tedious. My thought/hope is to slap a barcode on every single plate and log those barcodes into a database. I would then like to search the two barcodes on either side of the weld to lookup the weld we are working on. So scan the barcode on the left plate (which would have up to 4 welds associated with it, one for each side) and then scan the barcode on the right plate (which would then zero in on which of the 4 options from the first scan we are looking for). This would then pull the record for the weld and we could record progress on it for the day very quickly without typing in all the search characters.

So the question, is this doable? Our field crews have iPads so it seems like a good solution if it can be implemented. The table could be pre-populated with all the details of the weld, so only input would be something like % complete.

Thoughts? Even if not doable right in airtable (preferred), could a (VERY) simple app be drawn up to do this?